Technology

Value through cutting-edge technologyOperating principle

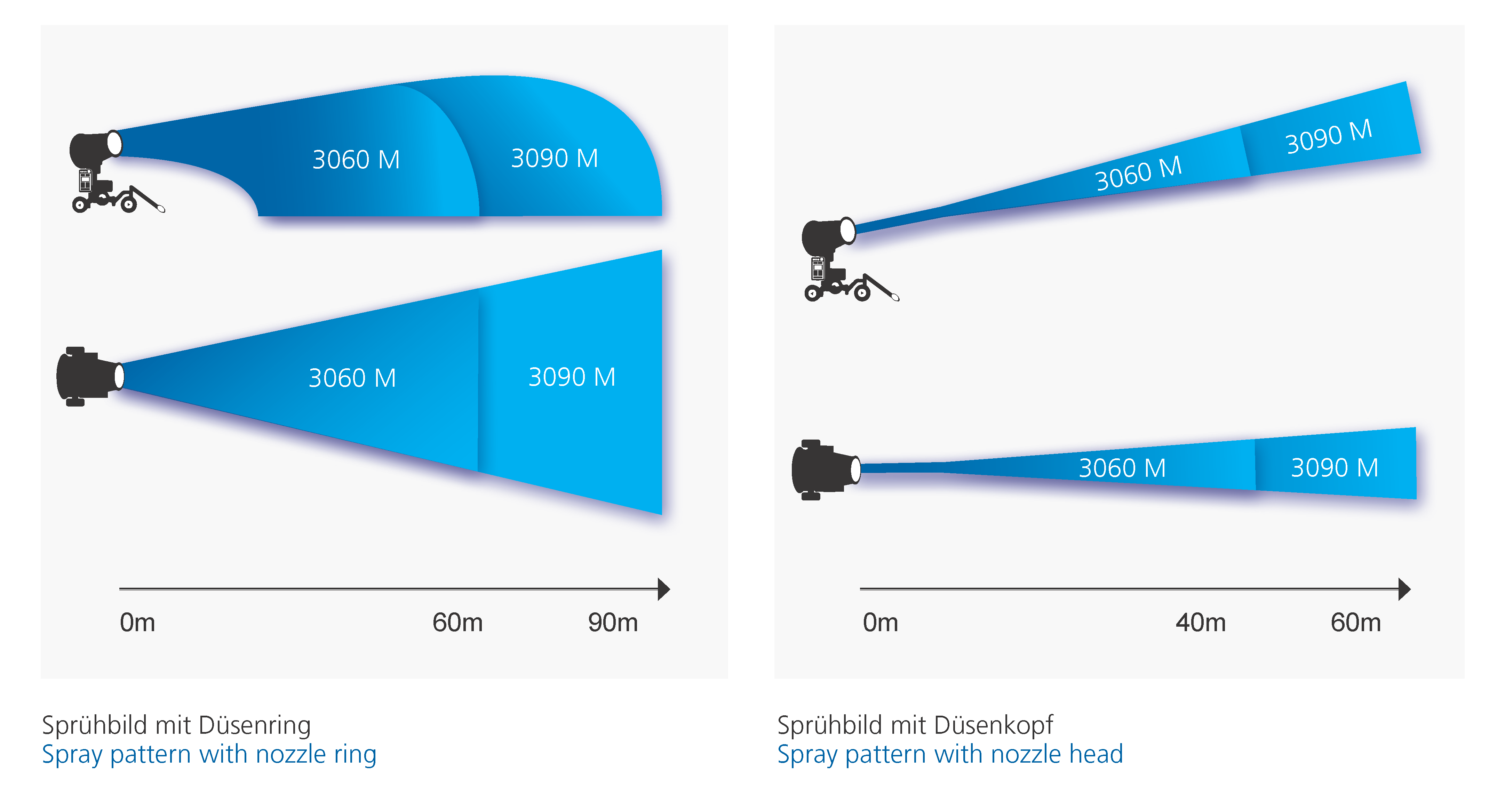

All MobyDick Systems for dust containment work in accordance with the principle of dust control using the finest water droplets. A modern high-pressure pump, combined with a powerful filter system, special nozzles, and an aerodynamically shaped high-performance cone (turbine), ensures an optimal droplet size and spread. These can be directed at the dust source as required via the nozzle ring (large-area distribution), the nozzle head (targeted dust binding) or a combination of both methods. The fine water droplets combine with the flying dust particles, causing them to quickly sink to the ground. The result: Significantly reduced dust pollution for people and environment.

High-performance cone:

The high-performance cone (turbine) developed in collaboration with the Institute of Aerodynamics at the Zurich University of Applied Sciences (ZHAW) is made of robust, glass fibre-reinforced plastic and impresses with its high corrosion resistance, noise reduction and straightforward repair options. Thanks to its innovative shape (reflexed aerofoils) and the integrated stators, it achieves an outstanding level of efficiency. The airflow generated creates a powerful thrusting effect that precisely transports the fine water droplets to the source of the dust, thereby ensuring efficient dust binding.