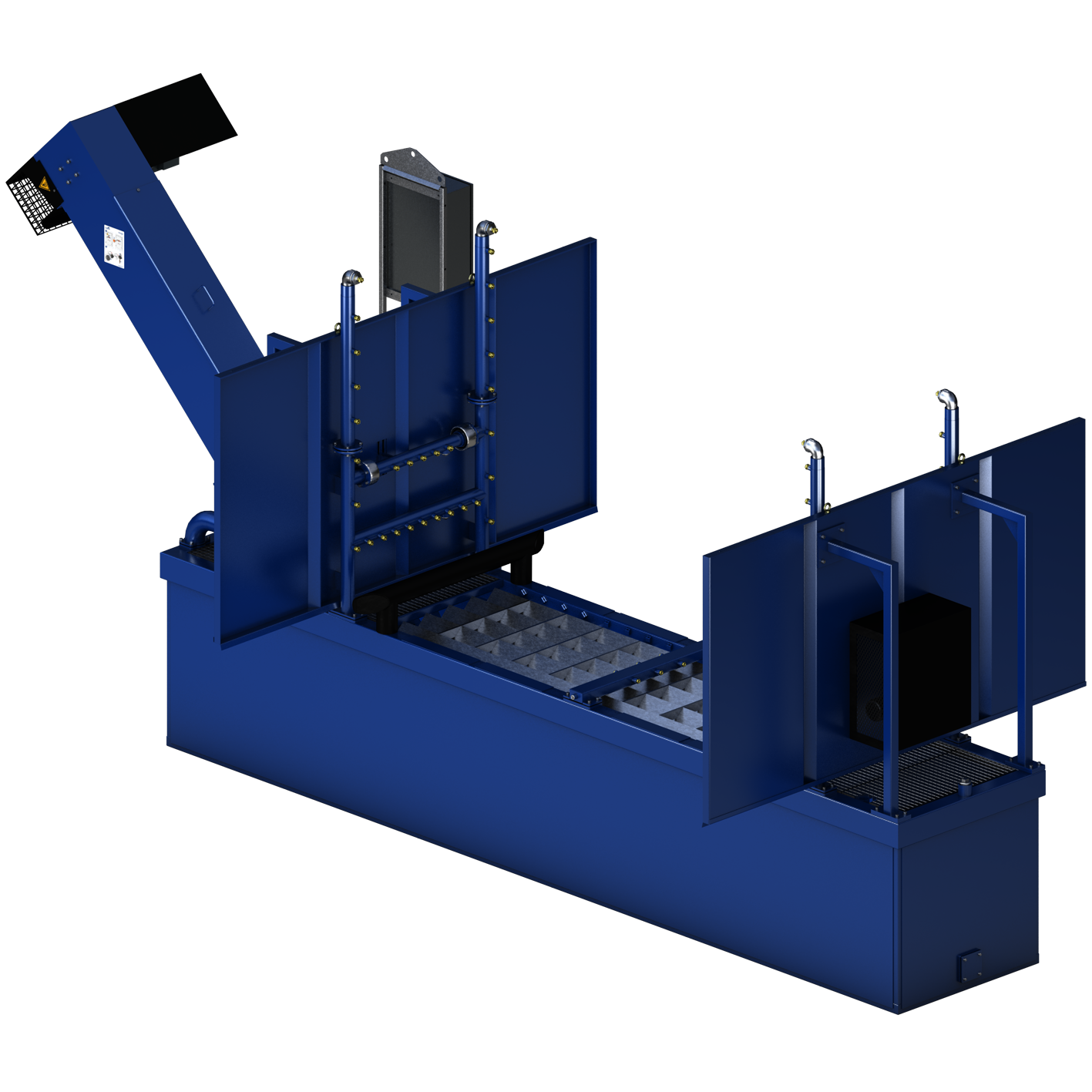

Demucking

Primary cleaning of wheeled and track vehicles

Construction machinery, military vehicles, and rail vehicles are often heavily soiled during operation. They must be washed before repair and service. A MobyDick Demucking system can do this in just a few minutes!

Areas of application:

- Military cehicles

- Construction vehicles

- HGVs and SUVs

- Rail vehicles

Good to know:

The demucking technology used allows most of the dirt on wheeled and chain track vehicles to be automatically removed at low pressure and without chemicals. The washing water flows back into the system during the cleaning process. This water is then reprocessed for the next washing operation.

Our product lines

Frequently Asked Questions (FAQ)

-

Demucking is an automatic cleaning technology for construction machines, military vehicles and railroad cars, offered by the Swiss FRUTIGER Company AG. The technology makes it possible to clean chassis, underbody and crawler tracks of vehicles in the shortest possible time.

-

Demucking consists of two cleaning steps. In the first step, over 80% of the dirt on wheeled and tracked vehicles is removed with water using low pressure and no chemicals. In the second step, fine cleaning is performed using high-pressure lances.

How much time does demucking save compared to conventional cleaning methods?

With a demucking system, washing times can be significantly reduced compared to conventional cleaning methods. The first automatic cleaning step with a MobyDick demucking system takes a few minutes while the second cleaning step, fine cleaning, takes only a few minutes instead of hours.

-

Demucking not only saves time, but also large amounts of water and chemicals. Since the washing water and the sludge washed off are hardly contaminated due to the low pressure, it can be recycled for the next washing process. This reduces the environmental impact.

-

Demucking is often used by companies in the construction and extraction industries, as well as by construction equipment rental companies. Military installations are also increasingly using MobyDick Demucking technology to wash army vehicles including tanks.

-

Yes, by adapting the technology from MobyDick tire washing systems, which have been successfully used for over 30 years, MobyDick demucking systems are easy to operate and require little maintenance and wear.

-

Demucking can be used by employees of maintenance departments of construction companies, military and railroad companies who want to relieve themselves from tedious cleaning work with high-pressure lances.

-

Depending on the size and equipment, a MobyDick demucking system usually costs between EUR 50’000 – 500’000.